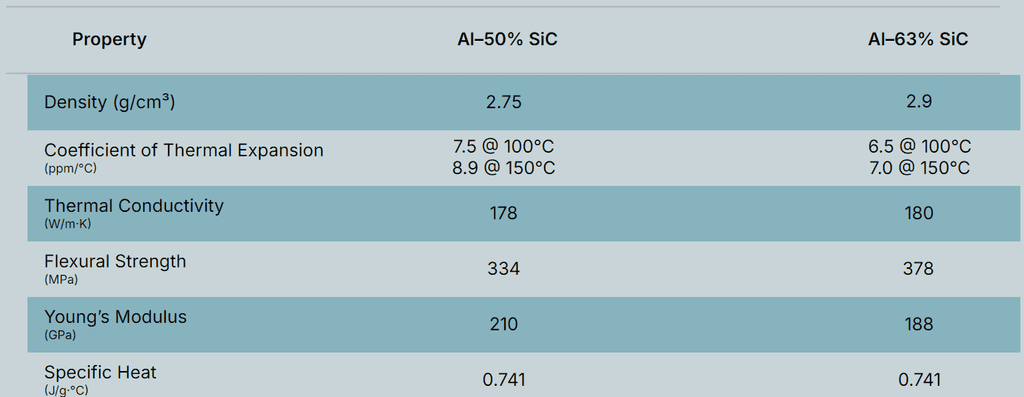

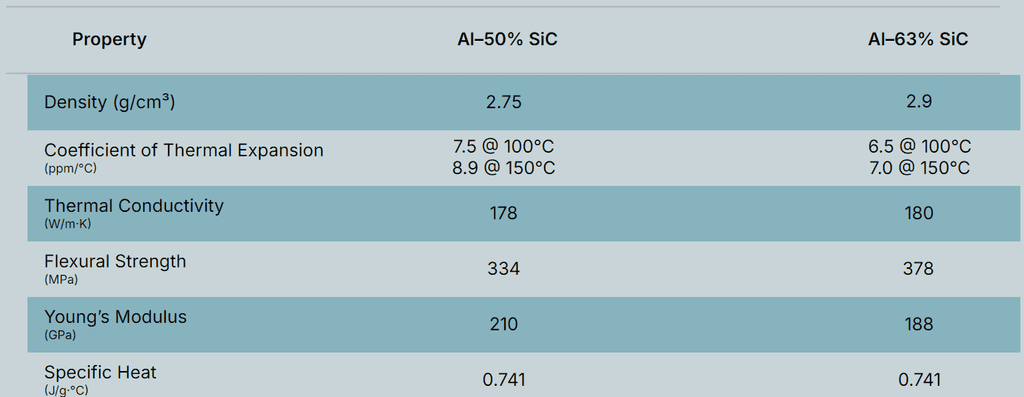

Property

Al–50% SiC

Al–63% SiC

Density (g/cm³)

2.75

2.9

Coefficient of Thermal Expansion

(ppm/°C)

7.5 @ 100°C

8.9 @ 150°C

6.5 @ 100°C

7.0 @ 150°C

Thermal Conductivity

(W/m·K)

178

180

Flexural Strength

(MPa)

334

378

Young’s Modulus

(GPa)

210

188

Specific Heat

(J/g·°C)

0.741

0.741

Advantages of Al-SiC Materials:

① Capable of mass production

② Adjustable coefficient of thermal expansion (depending on the ratio of aluminum to silicon carbide)

③ Resistant to thermal fatigue and degradation

④ Manufacturable in various shapes

⑤ Product surface can be electroplated or coated with thermal dissipation or insulating materials

Advantages of Al-SiC Materials:

① Capable of mass production

② Adjustable coefficient of thermal expansion

(depending on the ratio of aluminum to silicon carbide)

③ Resistant to thermal fatigue and degradation

④ Manufacturable in various shapes

⑤ Product surface can be electroplated or coated

with thermal dissipation or insulating materials

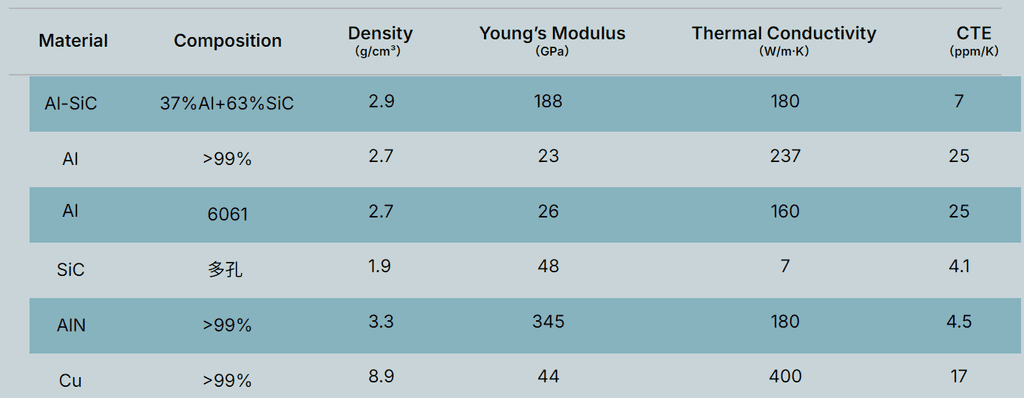

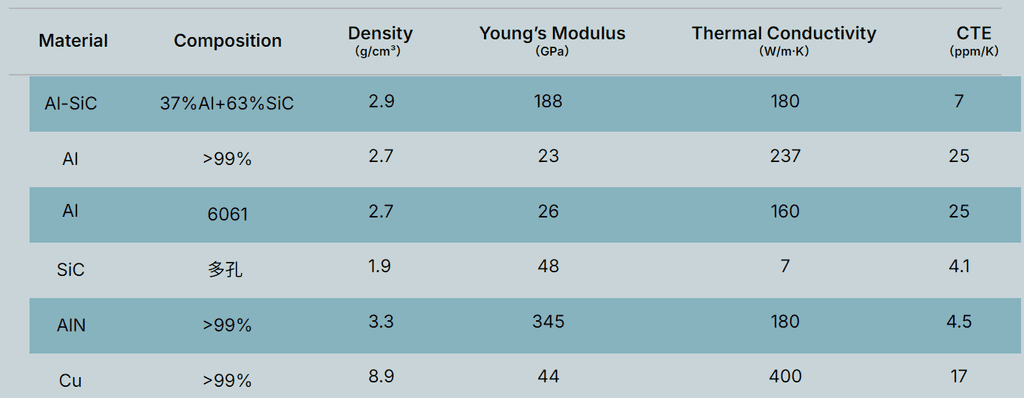

Material

Composition

Density

(g/cm³)

Young’s Modulus

(GPa)

Thermal Conductivity

(W/m·K)

CTE

(ppm/K)

Al-SiC

37%Al+63%SiC

Al

>99%

Al

6061

SiC

多孔

AlN

>99%

Cu

>99%

2.9

2.7

2.7

1.9

3.3

8.9

188

23

26

48

345

44

180

237

160

7

180

400

7

25

25

4.1

4.5

17

③ Lightweight Al-SiC can be applied in thermal management of electronic components, automotive industry,

high-precision machinery, green energy systems, and aerospace components..

① Al-SiC is structured with low thermal expansion coefficient (CTE) SiC and metallic aluminum with excellent thermal conductivity.

SiC provides heat dissipation, while Al ensures efficient heat transfer. Together, they deliver stable performance in conduction,

convection, and radiation, achieving superior thermal management.

② Within Al-SiC, the covalently bonded ceramic particles contribute to a high Young’s modulus.

Its wear resistance and mechanical toughness are also key advantages (flexural strength: 378 MPa).

② Within Al-SiC, the covalently bonded ceramic particles

contribute to a high Young’s modulus.

Its wear resistance and mechanical toughness are also

key advantages (flexural strength: 378 MPa).

③ Lightweight Al-SiC can be applied in

thermal management of electronic components,

automotive industry, high-precision machinery,

green energy systems, and aerospace components..

① Al-SiC is structured with low thermal expansion

coefficient (CTE) SiC and metallic aluminum with

excellent thermal conductivity.

SiC provides heat dissipation, while Al ensures

efficient heat transfer. Together, they deliver stable

performance in conduction, convection, and radiation,

achieving superior thermal management.

Material Characteristics

Material Characteristics

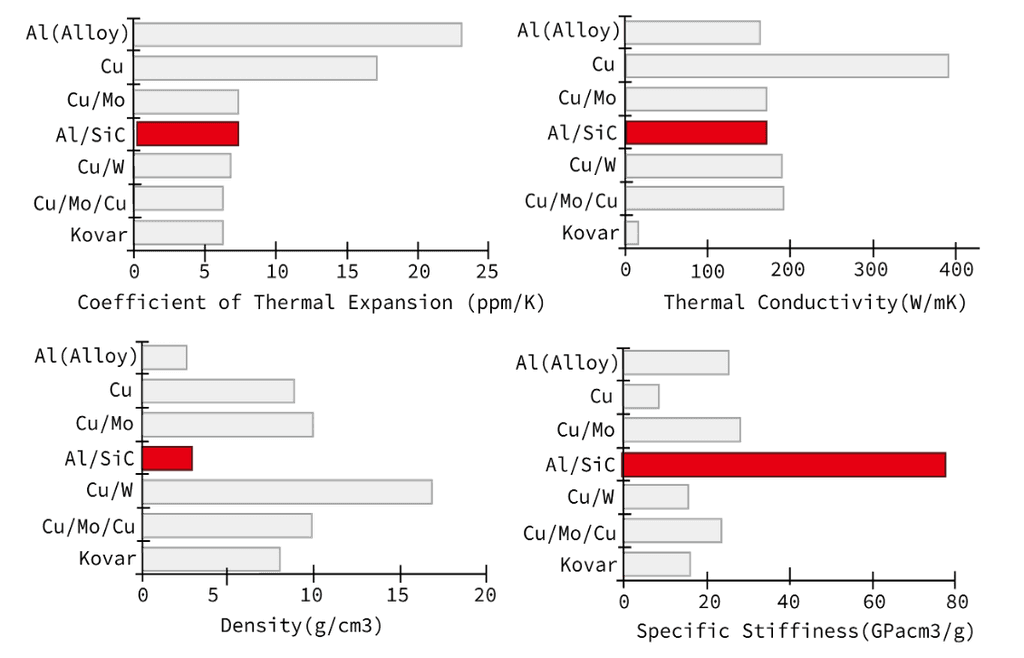

Material Comparisons

Research on Various Thermal Baseplate Materials

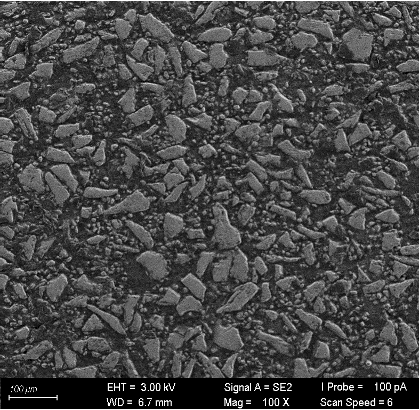

Al-SiC Cross-Section Metallographic Structure

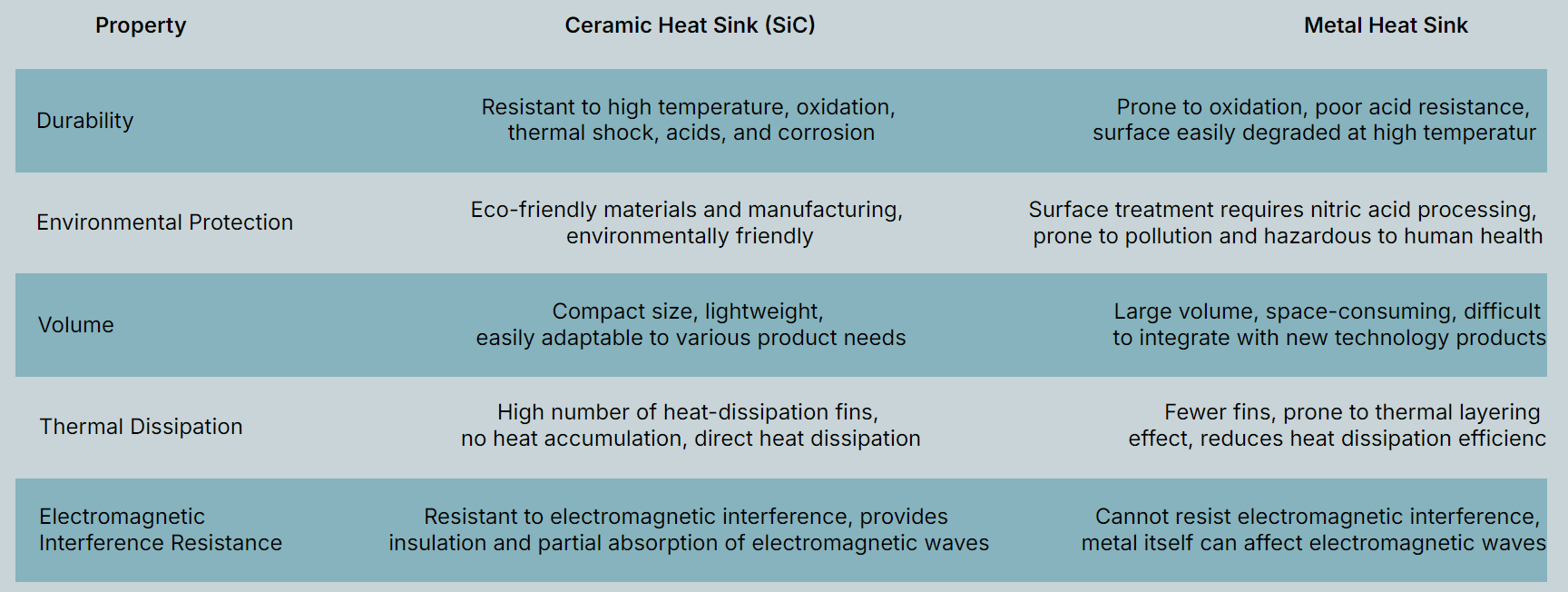

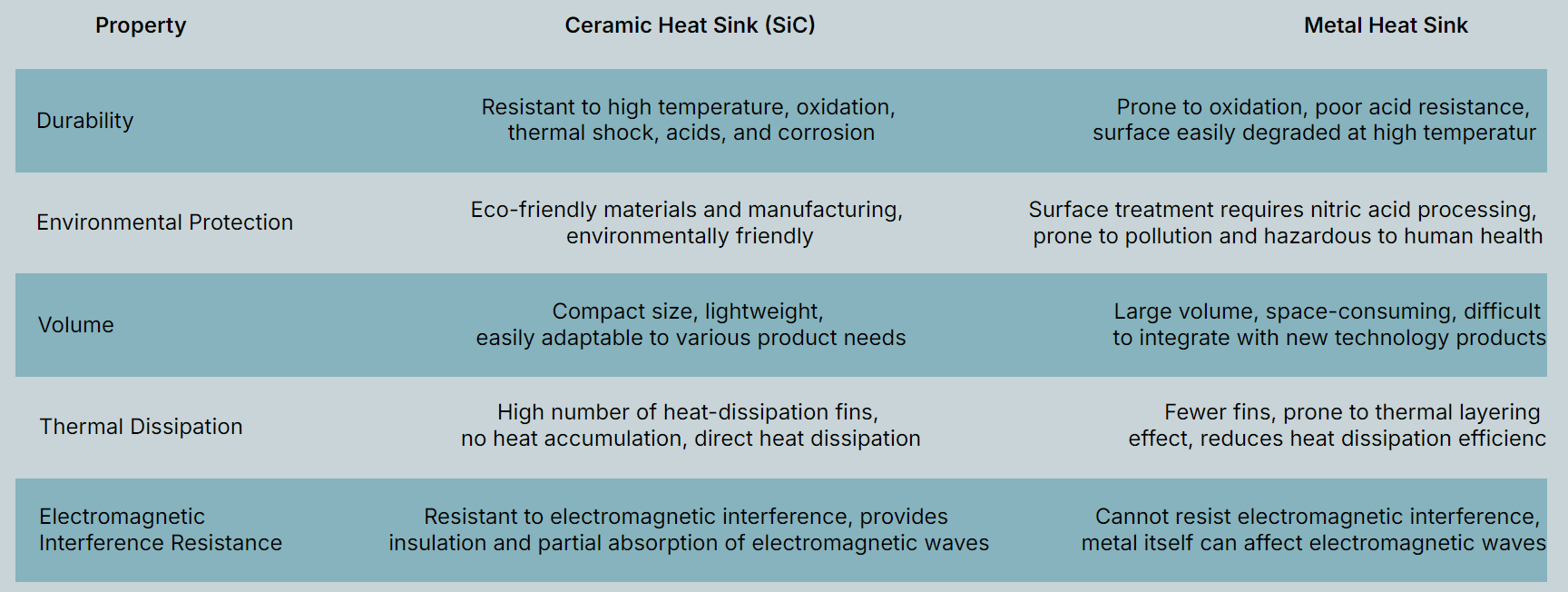

Property

Ceramic Heat Sink (SiC)

Metal Heat Sink

Durability

Resistant to high temperature, oxidation,

thermal shock, acids, and corrosion

Prone to oxidation, poor acid resistance,

surface easily degraded at high temperatur

Environmental Protection

Eco-friendly materials and manufacturing,

environmentally friendly

Surface treatment requires nitric acid processing,

prone to pollution and hazardous to human health

Compact size, lightweight,

easily adaptable to various product needs

Volume

Large volume, space-consuming, difficult

to integrate with new technology products

Thermal Dissipation

High number of heat-dissipation fins,

no heat accumulation, direct heat dissipation

Fewer fins, prone to thermal layering

effect, reduces heat dissipation efficienc

Resistant to electromagnetic interference, provides

insulation and partial absorption of electromagnetic waves

Electromagnetic

Interference Resistance

Cannot resist electromagnetic interference,

metal itself can affect electromagnetic waves

Comparison of SiC Ceramic Heat Sinks and Metal Heat Sinks

Comparison of SiC Ceramic Heat Sinks

and Metal Heat Sinks

Electromagnetic Interference Resistance

Research on Various Thermal Baseplate Materials

Al-SiC Cross-Section Metallographic Structure